Centrifugal pumps are unique and important members of the industrial world. The purpose of a centrifugal pump is to move fluid in a controllable fashion by engaging the fluid with strong rotational kinetic energy. This rotational energy increases the pressure of a fluid during the pumping process. While centrifugal pumps are sometimes used to raise liquid levels, they are most often used to induce a pressurized liquid flow. Read More…

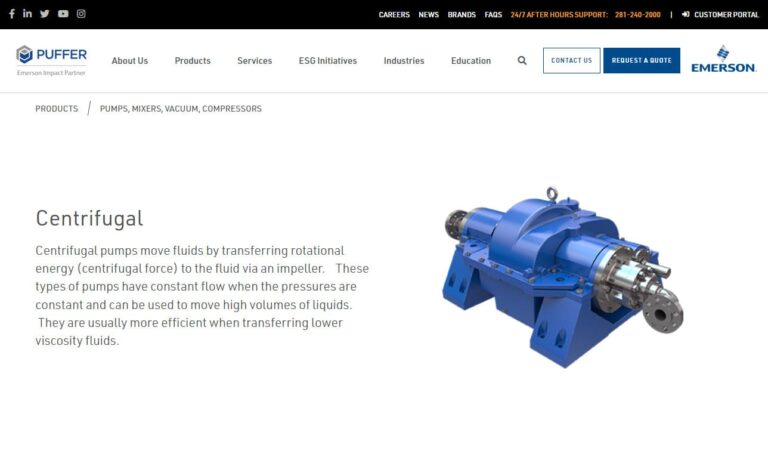

At Puffer Sweiven Rotating Equipment, we take pride in delivering dependable centrifugal pump solutions that keep critical operations running smoothly across process industries. We draw on decades of field experience and technical expertise to help our customers select, install, and maintain centrifugal pumps that meet demanding performance, reliability, and efficiency requirements.

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

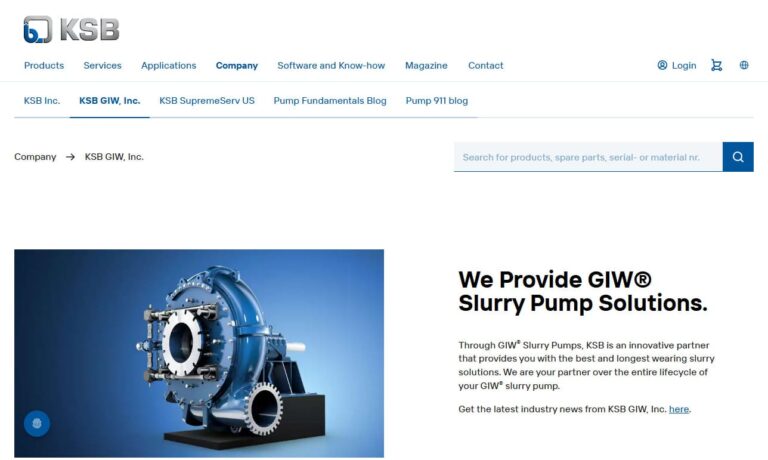

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

At Xylem, we take pride in advancing water technology through innovation and engineering excellence. Our centrifugal pumps are designed to deliver dependable, efficient performance across a broad range of industries and applications.

We are Pacer Pumps, a leading manufacturer of pumps and pumping solutions for a variety of applications. With over 50 years of experience in the industry, we are committed to providing our customers with high-quality, reliable products and exceptional service. At Pacer Pumps, we offer a wide range of pumps to suit a variety of needs, including centrifugal, self-priming, and hydraulic-driven pumps.

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

At Baker Hughes, we design and manufacture centrifugal pumps that deliver exceptional reliability and efficiency across a wide range of industrial and energy applications. We engineer our pump systems to move fluids safely and consistently under the most demanding conditions, from upstream oil and gas operations to power generation and process industries.

More Centrifugal Pump Companies

Centrifugal pumps are a cornerstone of industrial fluid handling, belonging to the rotary machine family within the broader realm of industrial equipment. Designed to move liquids by transforming the rotational energy generated by an impeller into kinetic energy, centrifugal pumps enable efficient fluid transfer, circulation, and pressure generation. Their reliability, versatility, and efficiency have made them integral to sectors ranging from water treatment and chemical processing to oil & gas, agriculture, HVAC, food and beverage, pharmaceuticals, and power generation.

What is the History of Centrifugal Pumps?

Although centrifugal pumps were invented in Europe in the late seventeenth century and introduced to the U.S. in the early nineteenth century, their widespread adoption in the industrial world is a more recent phenomenon. For many years, positive displacement pumps dominated the market, overshadowing centrifugal pumps. It wasn’t until the early twentieth century, with the emergence of high-speed electric motors and steam turbines, that centrifugal pumps became a practical and popular choice. Over the past seventy-five years, advancements in engineering, materials, and high-speed technology have driven the rapid adoption of centrifugal pumps across a diverse range of industries.

Learn more about the history of centrifugal pumps…

Materials Used in Centrifugal Pump Construction

Centrifugal pumps are predominantly manufactured from durable, corrosion-resistant materials such as cast iron, stainless steel, bronze, and aluminum. The selection of pump materials is a critical factor influencing resistance to corrosion, chemical compatibility, and overall performance. In industries handling aggressive chemicals, acids, or high-temperature fluids, manufacturers often use specialty alloys and engineered plastics, including fluorocarbons and thermoplastics, for seals, gaskets, and other components to extend service life and reduce maintenance requirements.

Advances in materials science have broadened the range of options available for centrifugal pump construction, enabling end-users to select pump models tailored to specific process requirements, fluid types, temperatures, and environmental conditions. This flexibility ensures safe, efficient operation in even the harshest industrial environments, such as chemical processing plants, mining operations, and wastewater treatment facilities.

- Cast Iron: Widely used for general water transfer applications due to its strength and cost-effectiveness.

- Stainless Steel: Preferred for sanitary and corrosive process industries, such as food & beverage, pharmaceuticals, and chemical handling.

- Bronze: Common in marine, HVAC, and potable water systems for its corrosion resistance.

- Thermoplastics & Fluorocarbons: Used in applications requiring chemical resistance and lightweight construction.

Key Parts and Components of Centrifugal Pumps

While centrifugal pumps are available in a wide variety of models and configurations, their fundamental design is elegantly simple. Each pump comprises three primary elements:

- Impeller: The heart of the centrifugal pump, responsible for imparting kinetic energy to the fluid. It features a central hub (the “eye”) and several vanes that direct the movement of the liquid. Impellers vary in diameter, vane design (open, semi-open, closed), and rotational speed to accommodate different flow rates and pressures.

- Pump Casing (Volute): This is the outer shell that houses the impeller. The casing’s design transforms the high-velocity, low-pressure fluid leaving the impeller into a controlled, high-pressure flow. The volute shape, in particular, helps maximize energy conversion and efficiently directs flow toward the discharge port.

- Mechanical Assembly (Pumping Unit): This includes the rotating shaft, bearings, seals, and the driver—typically an electric motor, but sometimes a diesel engine or steam turbine. The shaft transmits rotational energy from the motor to the impeller, while mechanical seals and bearings ensure smooth operation and prevent leaks.

Additional key components include wear rings (to minimize leakage and wear), gaskets and O-rings (for sealing), and a baseplate or mounting frame (for stability). Many modern centrifugal pumps also include integrated sensors and instrumentation for real-time performance monitoring.

How Does a Centrifugal Pump Work?

The operating principle of a centrifugal pump is based on imparting kinetic energy to a fluid and converting that energy into pressure. Here’s how a typical centrifugal pump operates step-by-step:

- Fluid Intake: The pump draws fluid into the center (eye) of the rotating impeller via the suction port.

- Acceleration: As the impeller spins, vanes accelerate the fluid outward by centrifugal force, dramatically increasing its velocity.

- Energy Conversion: The high-velocity fluid enters the pump casing, where a gradual expansion (the volute or diffuser) slows it down, converting kinetic energy into pressure.

- Discharge: The pressurized fluid exits the pump through the discharge port, ready for transport through the system.

The impeller’s offset placement within the casing, especially near the cutwater, optimizes the conversion of energy and maximizes discharge pressure. This process allows centrifugal pumps to efficiently transfer fluids over long distances or to elevated locations, making them suitable for water supply, HVAC circulation, irrigation, and industrial process applications.

Advantages and Disadvantages of Centrifugal Pumps

Centrifugal pumps offer numerous advantages that make them the preferred choice for many industrial, commercial, and municipal fluid handling applications. Key benefits include:

- Simple Design and Maintenance: Minimal moving parts reduce wear, simplify maintenance procedures, and minimize downtime.

- High Efficiency: Capable of handling large flow rates and producing significant discharge pressures, making them ideal for a wide spectrum of flow and head requirements.

- Versatile Fluid Handling: Suitable for a broad range of liquids, including clean water, corrosive chemicals, light slurries, and even some liquids containing suspended solids.

- Compact Footprint: Typically lighter and more compact than positive displacement pumps, facilitating installation in confined spaces and reducing construction costs.

- Scalability and Flexibility: Can be configured in parallel (to increase capacity) or series (to increase pressure) for optimal system design. Many models can be customized with different materials, impeller designs, and sealing options to match specific process requirements.

- Reliable Performance: With proper selection and maintenance, centrifugal pumps offer long service life, high operational reliability, and reduced total cost of ownership.

Despite these strengths, centrifugal pumps are not without limitations. When evaluating whether a centrifugal pump is right for your application, consider the following drawbacks:

- Viscosity Sensitivity: Their efficiency drops significantly with high-viscosity fluids, which may require positive displacement pumps instead.

- Cavitation Risk: Improper suction conditions or inadequate net positive suction head (NPSH) can cause cavitation, damaging the impeller and reducing performance.

- Solids Handling Limitations: Standard designs are less effective for fluids with large or abrasive solids, which can cause premature wear or clogging. Specialized trash pumps or slurry pumps may be required.

- Performance Variability: Centrifugal pumps perform best within a defined range of flow and head; operation far outside this range can cause vibration, noise, or reduced efficiency.

- Priming Requirements: Many centrifugal pumps require priming (filling the casing with fluid) before operation, unless they are self-priming models.

- Noise and Vibration: Can generate noticeable noise and vibration, especially at high speeds, requiring proper mounting and balancing.

Types of Centrifugal Pumps and Their Applications

Centrifugal pumps come in a variety of designs, each tailored to specific tasks, industries, and fluid properties. Selecting the right type ensures optimal performance, reliability, and energy efficiency. Below are some of the most common types and their primary applications:

Types of Centrifugal Pumps by Application

- Water Pumps: Essential for water transfer, irrigation, municipal water supply, and HVAC circulation. Their lightweight construction and high-pressure capabilities make them suitable for both residential and commercial environments.

- Sump Pumps: Designed to prevent flooding in basements or low-lying areas by efficiently removing accumulated water. Pairing with a pressure tank enhances water distribution in residential systems.

- Trash Pumps: Engineered for rapid removal of contaminated water, sewage, sludge, or wastewater containing solids and debris. Deep impeller veins and large discharge ports enable the handling of viscous, abrasive fluids in construction, mining, and municipal applications.

- Jet Pumps: Combine a centrifugal pump with a jet (nozzle and venturi) to increase suction lift. Used in shallow and deep well applications, jet pumps are gradually being replaced by more efficient submersible pump technologies.

- Submersible Pumps: Designed for installation within wells, sumps, or tanks. These units are fully immersed in fluid and ideal for groundwater extraction, wastewater transfer, and dewatering applications.

- Self-Priming Pumps: Capable of evacuating air and priming themselves without manual intervention. Widely used in applications where the pump must start dry or after intermittent use.

- Hygienic/Sanitary Pumps: Built to meet stringent sanitation standards for food, beverage, dairy, and pharmaceutical industries. Features include stainless steel construction, clean-in-place (CIP) compatibility, and smooth surfaces to prevent bacterial growth.

Types of Centrifugal Pumps by Parts or Design

- Close-Coupled End-Suction Pumps: The impeller is mounted directly onto the motor shaft, making these pumps compact, easy to install, and maintain. Common in commercial HVAC, water supply, and light industrial processes.

- Axial Flow Pumps: Feature a vertical shaft and impeller designed to move large volumes of fluid at low pressure, typically used for flood control, drainage, and irrigation.

- Radial Flow and Mixed Flow Pumps: Radial flow pumps generate high head at low flow rates; mixed flow designs combine features of radial and axial flow for versatile performance.

- Multistage Centrifugal Pumps: Contain multiple impellers in series, enabling very high pressures for boiler feed, reverse osmosis, or high-rise building water supply.

Common Use Cases for Centrifugal Pumps

- Municipal Water Supply: Distributing potable water from treatment plants to consumers.

- Industrial Process Fluid Transfer: Moving chemicals, solvents, or process liquids within manufacturing facilities.

- HVAC Systems: Circulating hot or chilled water for heating/cooling in commercial buildings.

- Wastewater Treatment: Transferring, circulating, and aerating sewage and effluent in treatment plants.

- Irrigation and Agriculture: Supplying water to fields, greenhouses, and sprinkler systems.

- Fire Protection: Providing high-pressure water streams for fire suppression in residential, commercial, and industrial facilities.

- Oil & Gas Industry: Handling hydrocarbons, produced water, and chemical injection.

- Food and Beverage Manufacturing: Pumping dairy, juices, syrups, and CIP fluids safely and hygienically.

Key Considerations When Selecting a Centrifugal Pump

To achieve optimal performance and maximize service life, selecting the right centrifugal pump requires careful evaluation of several critical factors:

- Fluid Properties: Consider the fluid’s viscosity, temperature, chemical composition, presence of solids, and corrosiveness. The wrong pump or material can cause premature failure or inefficiency.

- Flow Rate and Head: Define the required system flow (typically in gallons per minute or liters per second) and the total dynamic head (vertical lift + system friction losses). Centrifugal pumps must be sized to operate efficiently at these conditions.

- NPSH (Net Positive Suction Head): Ensure the available NPSH exceeds the pump’s NPSH requirement to prevent cavitation. This is especially important in high-temperature or low-pressure applications.

- Impeller Design and Speed: Adjusting impeller diameter or speed can fine-tune performance. Using variable frequency drives (VFDs) allows real-time speed control for energy savings.

- Suction Conditions: Assess suction lift, pipe sizing, and altitude, as these directly affect pump priming and performance.

- Installation Environment: Consider space constraints, available power sources, safety requirements, and exposure to the elements.

- Regulatory Compliance: For sanitary, drinking water, or hazardous chemical applications, ensure the pump complies with relevant standards (e.g., ANSI, ISO, NSF, FDA).

- Maintenance and Serviceability: Choose designs that simplify inspection, cleaning, and part replacement. Access to local service centers and spare parts is also essential.

Choosing the Right Centrifugal Pump Supplier

Investing in a centrifugal pump is a significant decision that impacts operational efficiency, reliability, and total cost of ownership. To ensure a successful purchase, it’s crucial to evaluate multiple suppliers based on expertise, product range, customization options, after-sales service, and technical support.

Our comprehensive directory of centrifugal pump manufacturers and suppliers makes it easy to compare leading brands, review detailed business profiles, and connect directly with pump experts. Each supplier’s profile page highlights their experience, certifications, and areas of specialization. Users can efficiently request quotes, technical documentation, or consultation via integrated contact forms.

Take advantage of our patented website previewer to quickly assess a company’s focus areas, product lines, and industry expertise. Once you’ve identified potential suppliers, use our streamlined RFQ (Request for Quote) form to contact multiple companies simultaneously—saving you time and ensuring you receive competitive offers.

Want to ensure you select the best centrifugal pump manufacturer for your needs? Read about the steps to select the best centrifugal pump manufacturer.

FAQs: Centrifugal Pump Selection, Use, and Maintenance

- What is the difference between centrifugal and positive displacement pumps? Learn how flow characteristics and operating principles differ between pump types.

- What causes cavitation and how can I prevent it? Cavitation is usually caused by low suction pressure or high fluid temperature. Proper pump sizing, correct NPSH, and good suction piping design can prevent cavitation.

- Can centrifugal pumps handle abrasive or corrosive fluids? Yes, with the right material selection and design. Specialized slurry or chemical pumps are available for these applications.

- How often should I service my centrifugal pump? Service intervals depend on application, operating conditions, and manufacturer recommendations, but regular inspection of seals, bearings, and wear parts is key to reliable operation.

- What are common signs of pump failure or inefficiency? Look for reduced flow, unusual noises, vibration, seal leaks, or increased energy consumption as indicators of possible issues.

Summary: Why Choose a Centrifugal Pump?

Centrifugal pumps are the go-to solution for efficient, reliable, and cost-effective fluid movement across countless industries. Their combination of simple design, broad material compatibility, adaptability to a wide range of flows and pressures, and ease of maintenance ensures they meet the demands of everything from municipal water supply to high-tech process industries. By understanding the core components, working principles, advantages, and limitations of centrifugal pumps, buyers can make informed decisions that optimize system performance, reliability, and value.

When selecting a centrifugal pump, always consider the nature of the fluid, system requirements, operational environment, and the expertise of your chosen supplier. With the right pump and support, you’ll achieve efficient, trouble-free fluid handling for years to come.

Ready to find the perfect centrifugal pump for your application? Browse our directory of top centrifugal pump manufacturers and request a quote today!

What are the main materials used in centrifugal pump construction?

Centrifugal pumps are commonly made from cast iron, stainless steel, bronze, and aluminum. For handling aggressive chemicals or high-temperature fluids, specialty alloys and engineered plastics such as fluorocarbons and thermoplastics are also used to enhance corrosion resistance, chemical compatibility, and longevity.

How does a centrifugal pump work?

A centrifugal pump operates by drawing fluid into the center of a rotating impeller. The spinning impeller accelerates the fluid outward, increasing its velocity. The pump casing (often a volute) then converts this kinetic energy into pressure, and the pressurized fluid is discharged through the pump outlet for system use.

What are the advantages and disadvantages of centrifugal pumps?

Advantages include simple design, easy maintenance, high efficiency for large flows, versatility across many fluids, compact size, configurability, and reliable long-term performance. Disadvantages include reduced efficiency with high-viscosity liquids, risk of cavitation, limited solids handling for standard models, performance dependence on proper sizing, and possible priming requirements.

How can I choose the right centrifugal pump for my application?

To choose the right pump, consider the properties of your fluid (such as viscosity, temperature, and chemical makeup), desired flow rate and head, Net Positive Suction Head (NPSH), impeller design, suction conditions, installation environment, and compliance with industry regulations. Also factor in serviceability and support from the supplier.

What types of centrifugal pumps are available for different applications?

Types include water pumps, sump pumps, trash pumps, jet pumps, submersible pumps, self-priming pumps, and hygienic/sanitary pumps. Pumps can also be categorized by design, such as close-coupled end-suction, axial flow, radial/mixed flow, and multistage centrifugal pumps, each suited to specific industries and fluid properties.

What are the key components of a centrifugal pump?

The primary components are the impeller (which adds energy to the fluid), the pump casing or volute (which converts velocity to pressure), and the mechanical assembly (including shaft, bearings, seals, and motor or other driver). Additional parts may include wear rings, gaskets, O-rings, and integrated sensors.

What are some common use cases for centrifugal pumps?

Common uses include municipal water supply, industrial process fluid transfer, HVAC systems, wastewater treatment, irrigation and agriculture, fire protection, oil and gas, and food and beverage manufacturing. Their versatile design supports reliable operation across a wide range of industries.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services