The History of Centrifugal Pumps

The history of centrifugal pumps is a tale of engineering ingenuity, evolving from ancient concepts to modern marvels that power industries worldwide. These devices, which use rotational energy to move fluids, have roots stretching back centuries, with key developments shaping their design and application.

Early Foundations

The concept of using centrifugal force to move fluids dates to antiquity, though not in the form of a pump. In the late 15th century, Leonardo da Vinci sketched ideas for machines that spun to displace water, hinting at centrifugal principles. However, these remained theoretical. The first practical step came in 1687 when French physicist Denis Papin described a rudimentary centrifugal pump-like device—a spinning tube to lift water using centrifugal motion. Papin’s design was experimental and lacked efficiency, but it laid the groundwork.

19th Century Breakthroughs

The Industrial Revolution catalyzed the true birth of centrifugal pumps. In 1839, British inventor John Appold developed one of the earliest functional designs, featuring curved vanes within a rotating impeller—still a core element today. Appold’s pump was showcased at the 1851 Great Exhibition in London, demonstrating its ability to move large volumes of water efficiently. His innovation addressed limitations of earlier positive displacement pumps, which struggled with high flow rates.

Around the same time, American engineer James Stuart Gwynne patented a centrifugal pump in 1851, refining the impeller and casing design. These advancements coincided with the rise of steam power, which drove pump rotors, making them vital for mining, irrigation, and urban water supply. By the late 19th century, centrifugal pumps were widely adopted, with engineers like Osborne Reynolds contributing theoretical insights into fluid dynamics that improved their performance.

20th Century Advancements

The 20th century saw centrifugal pumps become industrial workhorses. The advent of electric motors in the early 1900s replaced steam engines, enhancing efficiency and compactness. During World War I and II, demand surged for pumps in military applications—fuel transfer, shipbuilding, and field irrigation—pushing designs toward durability and portability.

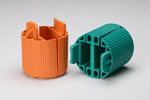

Material innovations also transformed centrifugal pumps. Early models used cast iron, but the mid-20th century introduced stainless steel, bronze, and plastics, improving corrosion resistance for chemical and wastewater handling. Multi-stage centrifugal pumps, stacking impellers for higher pressure, emerged by the 1930s, expanding their use in oil refineries and power plants.

Modern Era

Post-1950, centrifugal pump technology leapt forward with computer-aided design (CAD) and computational fluid dynamics (CFD). These tools optimized impeller shapes and volute casings, boosting efficiency and reducing energy use. Variable frequency drives (VFDs) introduced in the late 20th century allowed precise speed control, adapting pumps to fluctuating demands.

Today, centrifugal pumps dominate fluid movement—handling 70-80% of industrial pumping needs, from HVAC systems to desalination plants. Innovations like magnetic drive pumps (eliminating seals for leak-free operation) and smart pumps with IoT sensors reflect ongoing evolution. Their history mirrors humanity’s quest to harness physics for practical ends, evolving from da Vinci’s sketches to indispensable modern tools.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services