One of the things a building or house owner would never want to see is their basement flooded with sewage water. Not only would it damage the foundations of the building, but it would also become a demanding task to drain all the water. However, this will not be a problem if a sump pump is installed in the basement. Read More…

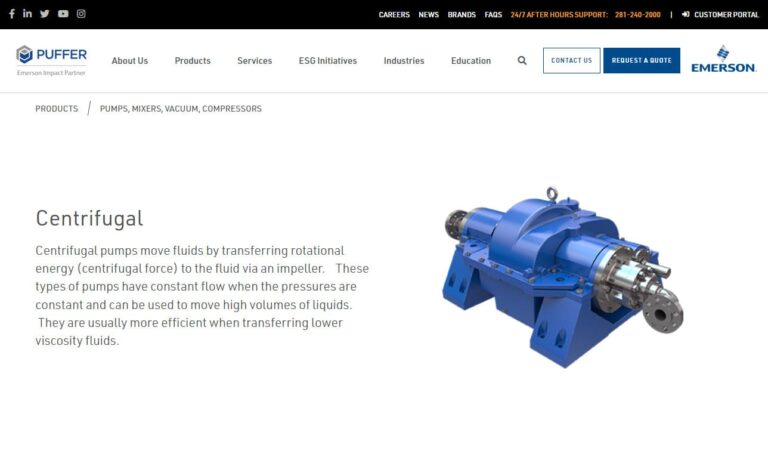

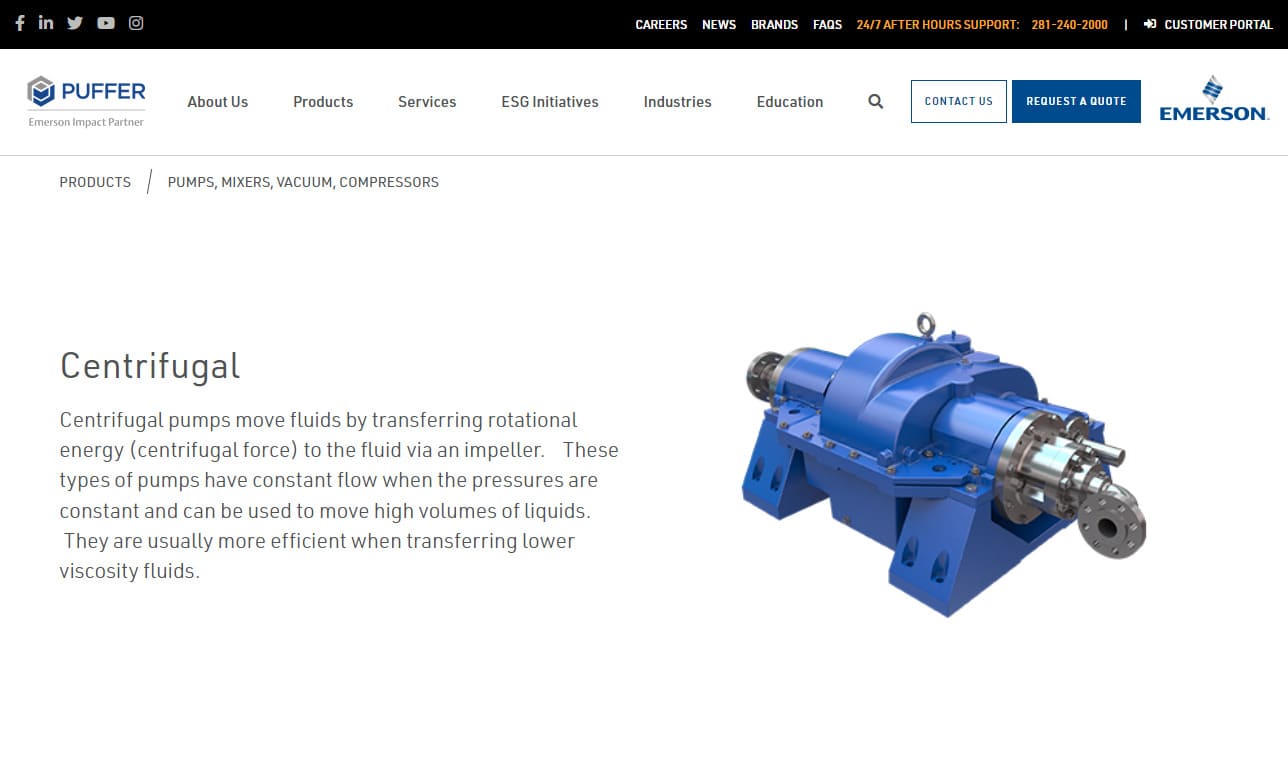

At Puffer Sweiven Rotating Equipment, we take pride in delivering dependable centrifugal pump solutions that keep critical operations running smoothly across process industries. We draw on decades of field experience and technical expertise to help our customers select, install, and maintain centrifugal pumps that meet demanding performance, reliability, and efficiency requirements.

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

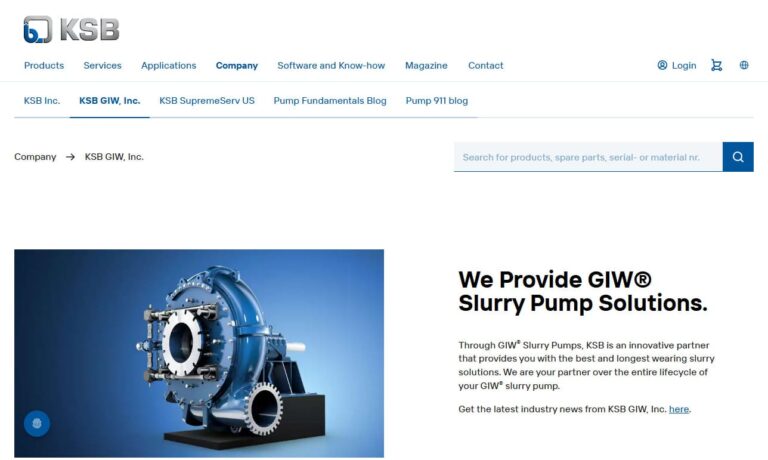

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

At Xylem, we take pride in advancing water technology through innovation and engineering excellence. Our centrifugal pumps are designed to deliver dependable, efficient performance across a broad range of industries and applications.

We are Pacer Pumps, a leading manufacturer of pumps and pumping solutions for a variety of applications. With over 50 years of experience in the industry, we are committed to providing our customers with high-quality, reliable products and exceptional service. At Pacer Pumps, we offer a wide range of pumps to suit a variety of needs, including centrifugal, self-priming, and hydraulic-driven pumps.

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

At Baker Hughes, we design and manufacture centrifugal pumps that deliver exceptional reliability and efficiency across a wide range of industrial and energy applications. We engineer our pump systems to move fluids safely and consistently under the most demanding conditions, from upstream oil and gas operations to power generation and process industries.

More Sump Pump Manufacturers

Introduction to Sump Pumps

A sump pump is a mechanical device installed in the basement of a building so it can dispose of accumulated water by pumping it out through discharge pipes. A sump is a pit or basin dug into the floor to collect leaking water. It is designed so that water falls into it due to the force of gravity.

As soon as the water fills the sump pit, the pump starts pumping it out of the house. Sumps not only pertain to domestic use but are employed in industrial areas too. A sump pump can discharge large amounts of industrial process water and high-temperature boiler condensate water.

How Does a Sump Pump Work?

Below are some of the features of a sump pump:

- A sump pump is a device that monitors rising water pressure and levels to make sure they don't go too high.

- These pumps measure the amount of water in the basin using a switch.

- When a rising water level triggers the switch, the pump begins pumping the water into a discharge pipe far from the house's foundation.

- An electric motor, a battery, or water can all be used to power a pump.

- While backup pumps that run on water or a battery during a power outage are common in sump pump systems, pumps primarily have a wired setup.

Switches Used in Sump Pumps

Sump pumps can be operated on a switch system. The pump can be turned on independently using the switch. Some switches function uniquely from others yet produce the same outcome. Here is a brief description of a few different switch kinds and how they operate:

- Pressure Switch: A pressure switch senses the amount of pressure in the water if it starts to rise and triggers the operation of the pump accordingly.

- Vertical Switch: This switch works on a simple mechanism. Being a magnetic switch, it slides up and down depending upon the water level, turning the pump on and off.

- Diaphragm Switch: This switch functions similarly to a human diaphragm, shifting from concave shape to normal (in or out) when the pressure changes. Because it is the least likely to become stuck on or off, it is the most frequently used type of switch.

Applications of Sump Pumps

Sump pumps are very specific with regards to their application. Following are some of the useful applications of sump pumps:

- Avoiding the growth of mold or mildew in basements

- Disposing of sewage or industrial wastewater

- Reducing humidity by improving air quality

- Keeping the temperature of a basement cool

Benefits of Sump Pumps

As evident from their applications, sump pumps can be beneficial in more than one way. Here is a list of the benefits of sump pumps:

- Preventing health or breathing hazards associated with mold and mildew growth

- Keeping a basement dry, clean, and free of flooding danger

- Protecting against sewage backups

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services