Selecting the right centrifugal pump manufacturer requires a systematic approach to ensure you get a reliable, high-quality product tailored to your needs. Here are the key steps to guide your decision:

- Define Your Application Needs

- Identify Requirements: Determine the pump’s purpose—e.g., water supply, chemical processing, irrigation, or wastewater management. Specify flow rate (GPM or m³/h), head (pressure), fluid type (e.g., corrosive, abrasive, viscous), and operating conditions (temperature, continuous or intermittent use).

- System Compatibility: Ensure the pump fits your system’s piping, power supply (e.g., electric, diesel), and space constraints.

- Research Manufacturer Expertise

- Industry Experience: Look for manufacturers with a proven track record in your sector. For example, a chemical plant needs a supplier skilled in corrosion-resistant pumps, while HVAC demands energy-efficient designs.

- Specialization: Check if they offer pumps suited to your needs—single-stage for low pressure, multi-stage for high pressure, or submersible for underwater use.

- Evaluate Product Quality

- Materials: Verify that the manufacturer uses durable materials like stainless steel, cast iron, or specialized alloys for your fluid type. Ask about impeller and casing durability.

- Standards Compliance: Ensure pumps meet industry standards—e.g., ISO 5199 for general use, API 610 for oil and gas, or ANSI for interchangeability. Certifications indicate reliability.

- Performance Specs: Request pump curves (flow vs. head) to confirm efficiency and suitability.

- Assess Manufacturing Capabilities

- Production Capacity: Confirm they can handle your order size—whether a single unit or bulk production—without compromising quality.

- Customization: If you need tailored solutions (e.g., specific impeller designs or coatings), choose a manufacturer with in-house engineering and flexibility.

- Technology: Look for companies using modern tools like CFD (computational fluid dynamics) for design optimization or CNC machining for precision.

- Check Reliability and Support

- Lead Times: Ask about production and delivery schedules. A nearby manufacturer or one with strong logistics can reduce delays.

- After-Sales Service: Ensure they offer maintenance support, spare parts availability, and warranties (e.g., 1-5 years). Local distributors or service centers are a plus.

- Reputation: Read reviews, case studies, or ask for references from similar clients to gauge dependability.

- Compare Costs and Value

- Get Quotes: Request detailed pricing from multiple manufacturers, including pump cost, shipping, and potential extras (e.g., installation kits).

- Total Cost of Ownership: Factor in efficiency (energy use), maintenance, and lifespan—not just upfront price. A cheaper pump with high operating costs may not save money long-term.

- Discounts: Inquire about bulk order discounts or long-term contracts if applicable.

- Verify Sustainability and Innovation

- Eco-Friendliness: If sustainability matters, choose a manufacturer using energy-efficient designs or recycled materials.

- Innovation: Opt for companies investing in modern features like VFD compatibility or smart monitoring for future-proofing.

- Test with a Trial Order

- Before committing fully, order a sample pump (if feasible) to evaluate performance, build quality, and service firsthand.

By following these steps, you’ll align your choice with operational needs, budget, and long-term reliability. For niche applications, prioritize manufacturers with relevant expertise—e.g., Goulds Pumps for industrial use or Grundfos for water systems. Narrow your options, then validate with data and feedback!

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

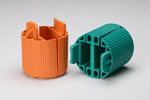

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services