Trash pumps are portable pumps that are typically used for applications requiring the removal of large volumes of water, including soft and hard materials, mud, leaves, twigs, sand, and sludge. Most trash pumps are robust, portable centrifugal pumps with wider discharge openings and deeper impeller vanes than other pumps. Trash pumps can move hundreds, if not thousands, of gallons per minute and can process materials that have some suspended particulates that can clog other centrifugal pumps. Read More…

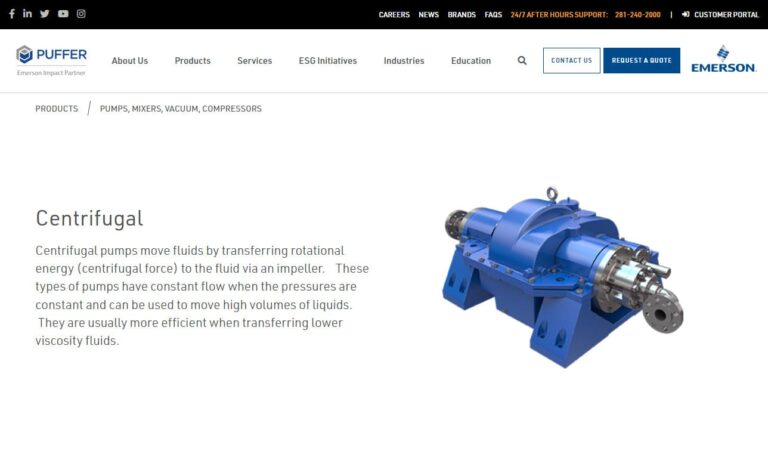

At Puffer Sweiven Rotating Equipment, we take pride in delivering dependable centrifugal pump solutions that keep critical operations running smoothly across process industries. We draw on decades of field experience and technical expertise to help our customers select, install, and maintain centrifugal pumps that meet demanding performance, reliability, and efficiency requirements.

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

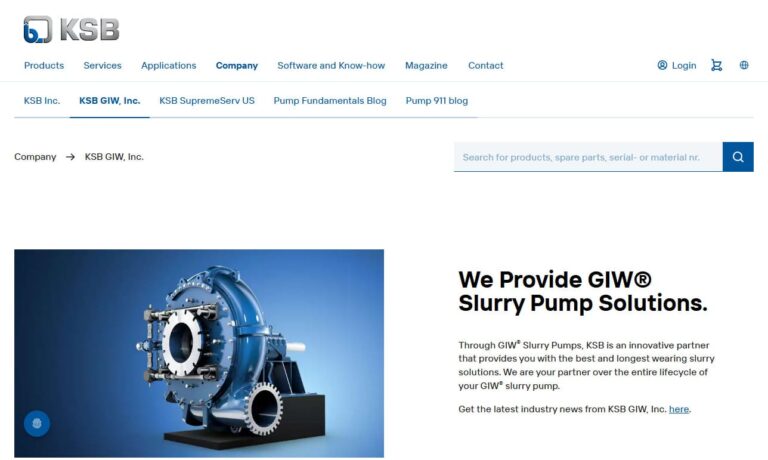

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

At Xylem, we take pride in advancing water technology through innovation and engineering excellence. Our centrifugal pumps are designed to deliver dependable, efficient performance across a broad range of industries and applications.

We are Pacer Pumps, a leading manufacturer of pumps and pumping solutions for a variety of applications. With over 50 years of experience in the industry, we are committed to providing our customers with high-quality, reliable products and exceptional service. At Pacer Pumps, we offer a wide range of pumps to suit a variety of needs, including centrifugal, self-priming, and hydraulic-driven pumps.

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

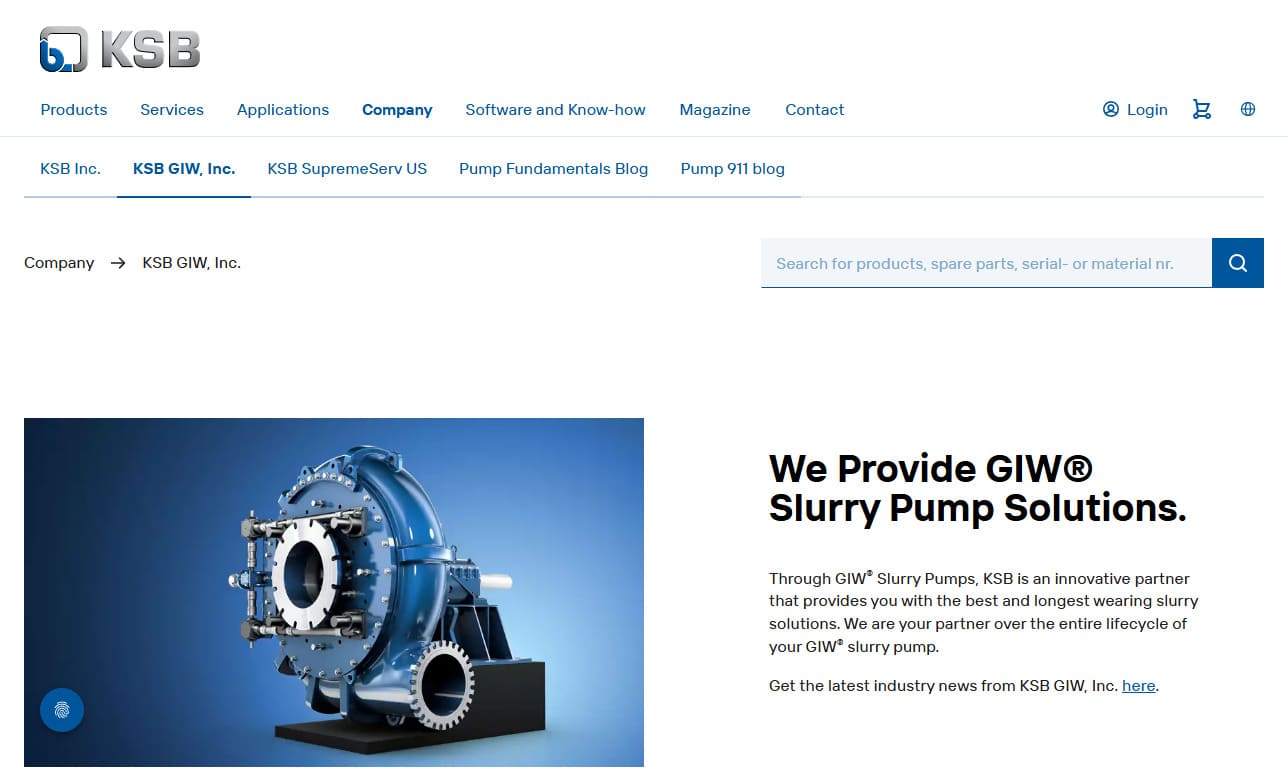

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

At Baker Hughes, we design and manufacture centrifugal pumps that deliver exceptional reliability and efficiency across a wide range of industrial and energy applications. We engineer our pump systems to move fluids safely and consistently under the most demanding conditions, from upstream oil and gas operations to power generation and process industries.

More Trash Pump Manufacturers

Trash pumps are heavy-duty, high-capacity pumps designed specifically for moving water that contains solids, debris, sludge, and various forms of waste material. Unlike grinders, the trash pump does not grind the materials that it receives, but instead moves them efficiently without clogging. These versatile pumps are engineered using durable materials such as cast iron, aluminum, steel, and stainless steel, ensuring long-lasting performance in demanding environments like construction sites, mining operations, wastewater treatment facilities, and flood control projects.

Trash pumps utilize a large inlet and robust power source to pick up debris while delivering maximum pressure and high discharge flow rates. Depending on the application, a trash pump can be powered by alternating current (AC) electricity, direct current (DC), compressed air, gasoline, diesel, or even solar energy. The flexibility in power options makes trash pumps suitable for a wide range of field conditions, remote locations, and emergency scenarios.

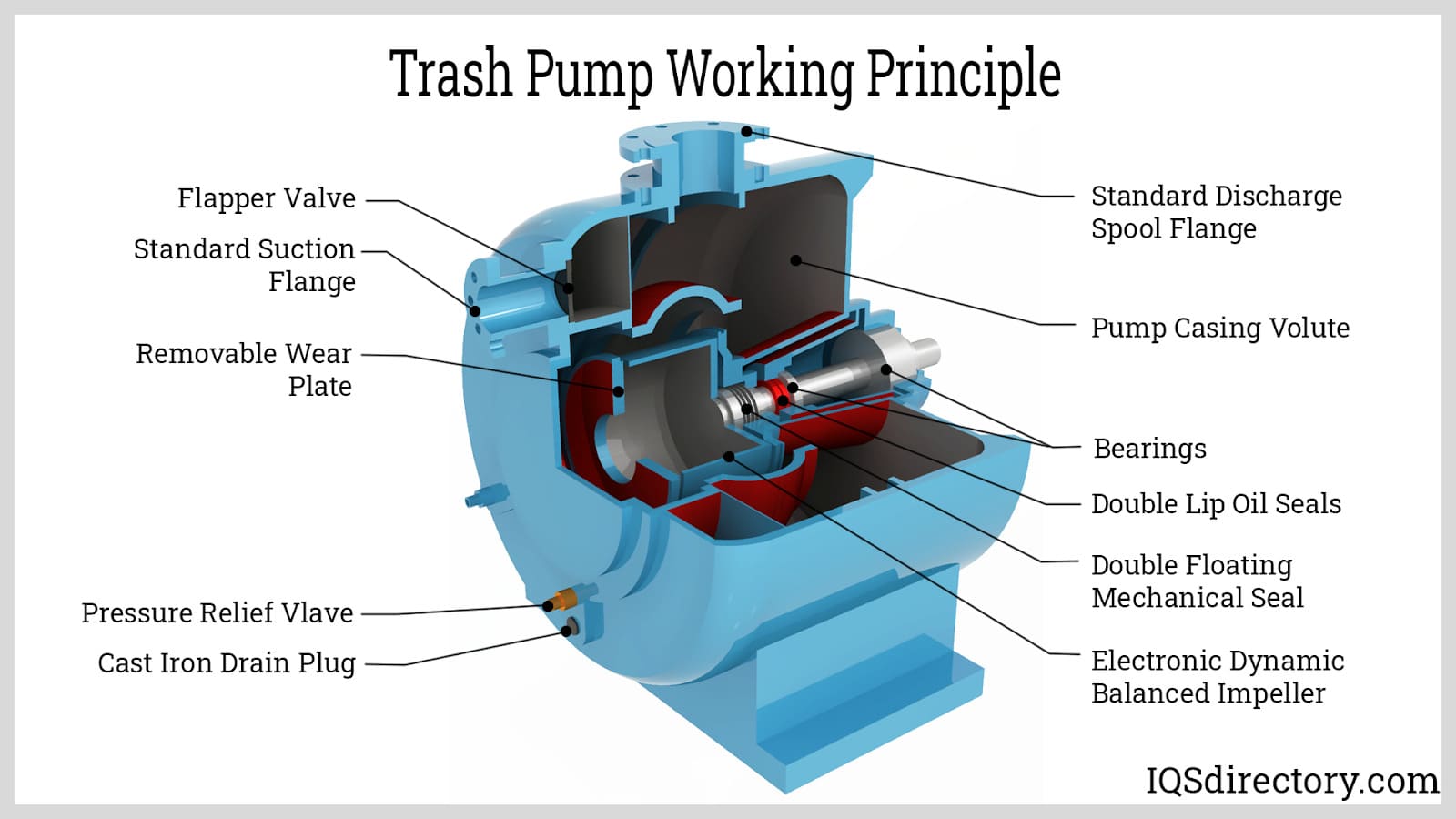

Trash Pump Working Principle

Understanding how a trash pump works is essential for selecting the right pump for your application. Trash pumps draw contaminated water—often filled with solid waste, sand, leaves, and other debris—and filter it before discharging it from the other end. The separation and movement process varies depending on the type of pump mechanism, but the most commonly used technology worldwide is the centrifugal trash pump due to its portability, efficiency, and ease of maintenance.

During operation, contaminated water is drawn into the pump. This occurs by generating a low-pressure zone within the pump cavity, which in turn pulls the liquid and suspended solids inside. The impeller, a rotating component, then imparts kinetic energy to the water and debris. Through the impeller’s centrifugal force, water is moved both axially and radially, propelling the mixture towards the pump’s discharge port. The volute casing collects and redirects the flow, converting velocity into pressure energy, thereby enabling the pump to efficiently process and discharge the fluid.

Trash pumps are engineered to keep debris, stones, and fibrous materials moving without blocking the system. The design ensures that larger solids can pass through the pump without causing damage or excessive wear.

It is important to note that trash pumps are not intended for pumping hazardous substances such as gasoline, caustic chemicals, or other fuels. Doing so can cause severe damage to the pump’s internal components and may result in safety risks or mechanical failures.

Did you know? High-temperature water can create cavitation issues within a trash pump. Cavitation occurs when static pressure drops below the liquid’s vapor pressure, forming vapor-filled cavities that can damage the pump’s impeller and reduce performance. Always check the water’s temperature before operation to avoid premature wear and costly repairs.

Key Features and Components of Trash Pumps

Modern trash pumps are equipped with specialized features that enable them to move large volumes of contaminated water containing significant amounts of solids and debris. Understanding these features can help you choose the right trash pump for your industrial, commercial, or municipal application.

Impeller

A core component of any centrifugal pump, the impeller in a trash pump is designed to limit clogging while maximizing flow and pressure. Unlike grinders, the impeller propels solids, fibrous materials, and grit through the pump without breaking them down. The unique shape and arrangement of the impeller blades generate a powerful liquid vortex inside the casing, effectively carrying debris out of the pump. For applications requiring the handling of large solids or stringy materials, look for trash pumps with a specially engineered non-clog or vortex impeller.

- Reduces risk of clogging, even in dirty water

- Enables continuous, high-volume pumping

- Low maintenance compared to other pump designs

Strainer

The strainer is fitted to the suction inlet of the trash pump. Its primary function is to prevent large debris, rocks, and particles—beyond the pump’s rated capacity—from entering and causing blockages or mechanical damage. When operating a trash pump, it is essential to keep the strainer fully submerged and clean to ensure optimal performance and prevent air from entering the system, which could lead to loss of prime and pump failure.

- Protects the pump from oversized debris

- Extends pump lifespan

- Maintains consistent flow rate

Self-Priming Capability

One of the standout features of quality trash pumps is their self-priming ability. Self-priming trash pumps are designed to evacuate air from the pump body and suction line, allowing them to start and operate efficiently without manual intervention. This is especially valuable for applications where the pump must be started and stopped frequently, or where the suction line may occasionally draw in air.

- Saves time and reduces manual labor

- Ensures readiness for emergency or flood control situations

- Ideal for intermittent and continuous operation

Durable Construction Materials

Depending on the intended use and the abrasiveness of the solids being pumped, trash pumps are available in a variety of materials including cast iron, ductile iron, stainless steel, and high-grade aluminum. For highly corrosive or abrasive environments, stainless steel or hard-coated components offer superior resistance and longer service life.

Heavy-Duty Seals and Bearings

To withstand the harsh conditions of pumping dirty water and solids, trash pumps are built with rugged seals and bearings that resist abrasion, corrosion, and frequent starts and stops. These features ensure reliable operation with minimal downtime.

Types of Trash Pumps: Which Is Right for Your Application?

While all trash pumps are designed to handle dirty water and debris, there are several types available, each tailored to specific industrial, municipal, or commercial use cases. Understanding the differences will help you select the best trash pump for your unique requirements. Wondering which trash pump type is best for your project? Consider the following options and their typical applications:

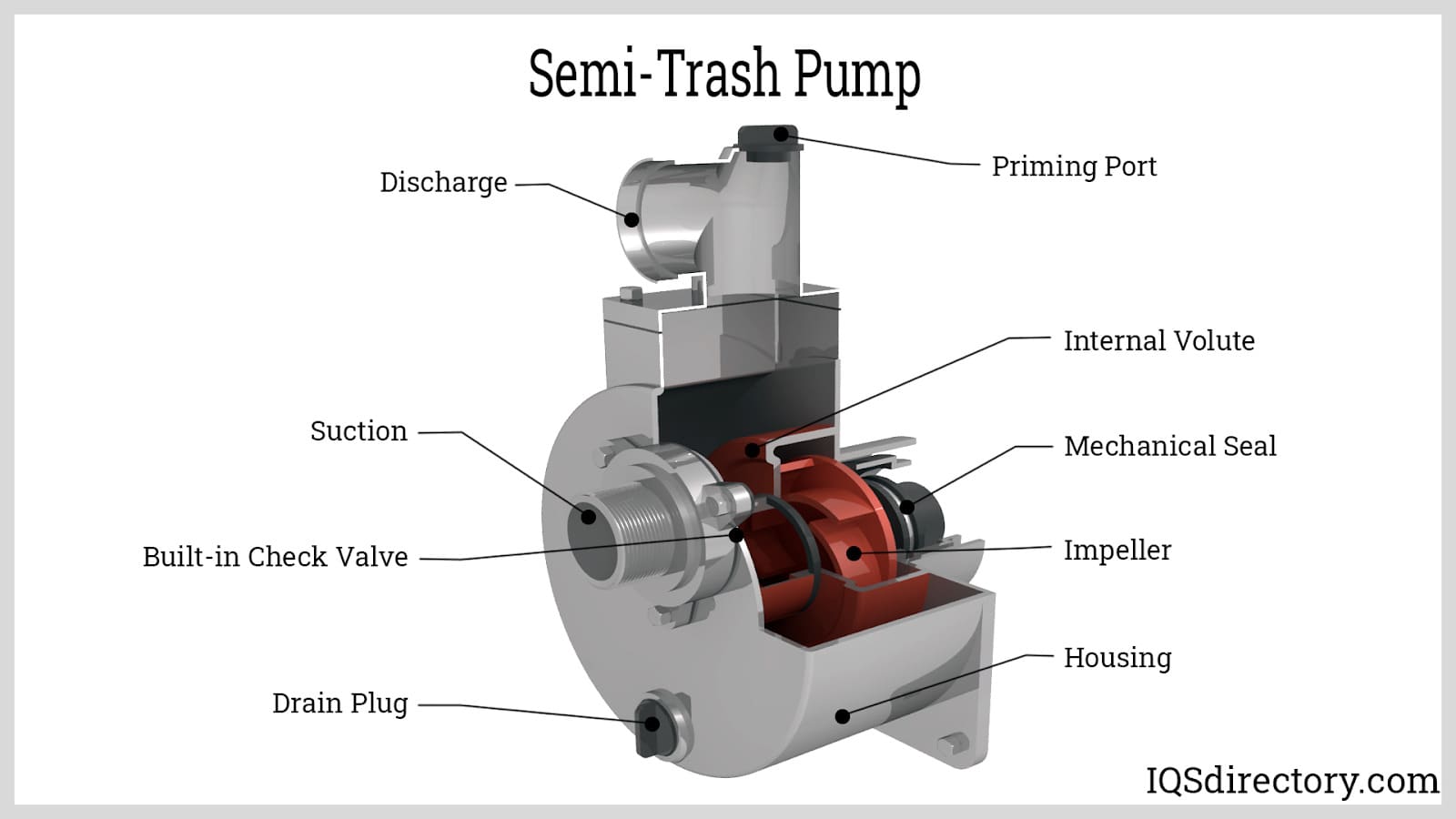

Semi-Trash Pumps

Designed for lighter-duty applications, semi-trash pumps feature smaller openings and are best suited for water with limited solid content—such as irrigation, dewatering fields, or light construction work. They can handle small debris (typically up to 5/8 inch in diameter), making them less likely to clog compared to standard pumps, but they are not intended for heavily solidified slurries or water containing large objects. For more rigorous tasks, standard trash pumps are a better fit.

Full Trash Pumps (Standard Trash Pumps)

Full trash pumps are designed for the toughest dewatering jobs, such as removing water from construction excavations, draining flooded basements, emptying ponds, or managing stormwater runoff. These pumps can handle larger solids (up to 1.5 inches or more in diameter) and are built for continuous, high-volume operation. Their robust construction and large impeller passages make them ideal for municipal, industrial, and agricultural use where reliability and high throughput are critical.

High-Pressure Trash Pumps

High-pressure trash pumps are engineered to deliver strong discharge pressure while still handling moderate amounts of solids. These pumps are commonly used for firefighting, irrigation, and applications where water must be moved over long distances or to higher elevations. If your job requires both debris handling and high lift, this type of pump is an excellent choice.

Diaphragm Trash Pumps

Diaphragm trash pumps are positive displacement pumps ideal for highly viscous fluids, sludge, and thick slurries. Rather than using an impeller, these pumps move water and debris using a flexible diaphragm. They excel in situations where the water contains a high percentage of solids, mud, or sediment, such as in mining, oilfield operations, and sewer bypass projects.

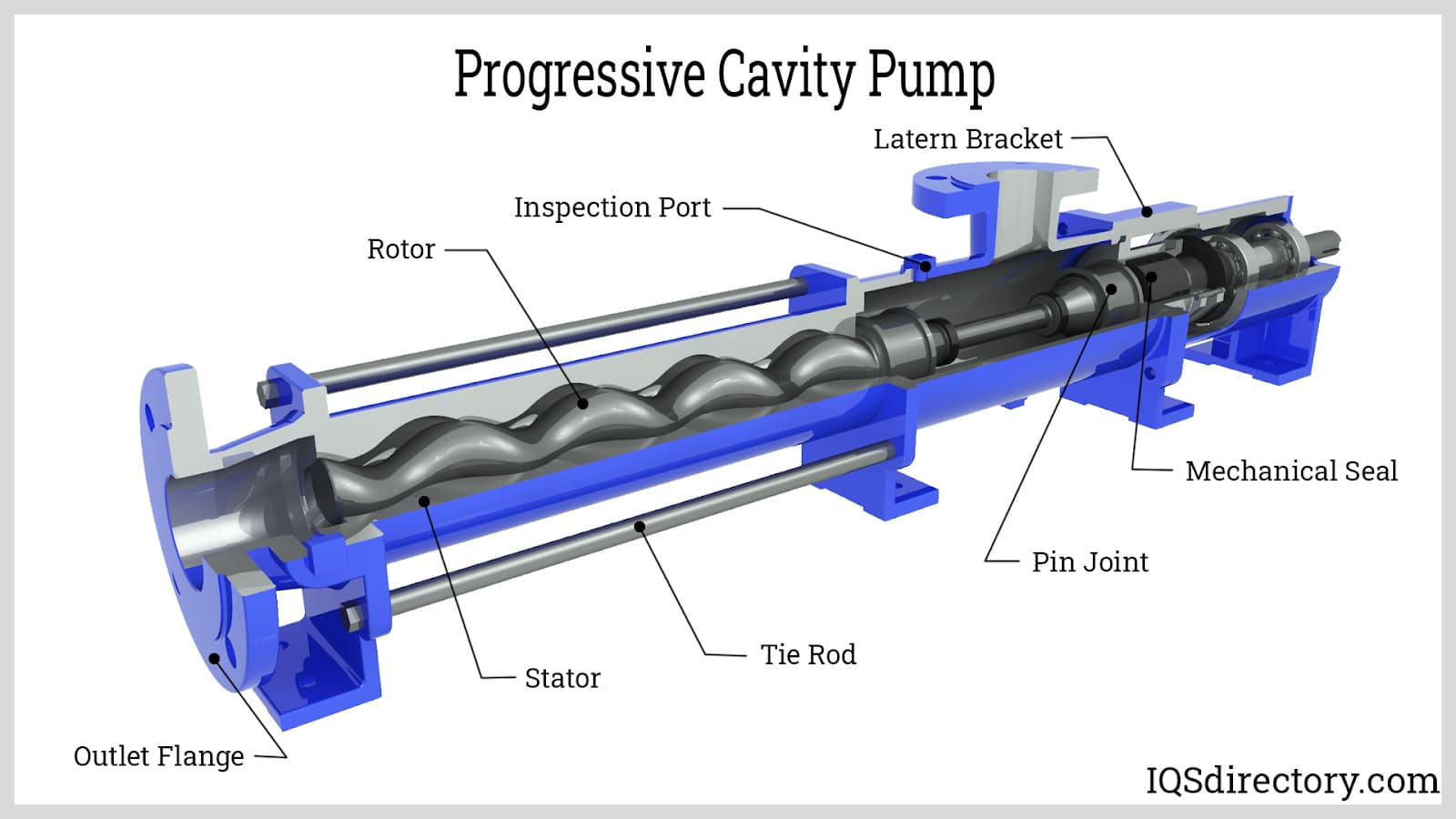

Progressive Cavity Pumps

Progressive cavity trash pumps are specifically designed to move slurries and liquids with suspended solids. The liquid enters the storage tank after flowing from the pump's delivery side to its suction side. These pumps are highly efficient in transporting viscous, slow-moving materials while maintaining a continuous flow. Progressive cavity pumps are also easy to clean and are often used in industrial processes requiring strict hygiene standards, such as food processing, chemical manufacturing, and wastewater treatment.

Positive Displacement Pumps

Positive displacement pumps use pistons, gears, diaphragms, or other mechanisms to move fluid by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe. These pumps are excellent for moving viscous or abrasive liquids under high pressure and are frequently used in industrial and chemical processing applications where precision and consistency are paramount.

Syringe Pumps

Syringe pumps are specialized positive displacement pumps that provide precise, programmable flow rates for laboratory, research, and medical applications. They are ideal for dosing, infusion, and withdrawal of liquids at controlled rates—ensuring accuracy in analytical or pharmaceutical processes.

Common Applications and Use Cases for Trash Pumps

Trash pumps are essential for a variety of industries and situations that involve moving contaminated water and solids. Typical applications include:

- Construction dewatering: Removing water from trenches, foundations, and excavation sites

- Municipal utility projects: Cleaning storm drains, sewer bypass, and flood control

- Industrial process water: Handling process waste, cooling water, and chemical slurries

- Agricultural irrigation and drainage: Pumping water with organic matter or sediment

- Mining and quarrying: Removing water and slurry from pits, tunnels, and shafts

- Emergency flood response: Quickly draining flooded areas during natural disasters

- Pond and lake maintenance: Removing silt, algae, and debris from water bodies

Looking for the best trash pump for your application? Consider the type and size of solids you need to move, the required flow rate and head (lift), the available power source, and the site conditions. If you need expert advice, contact a centrifugal pump specialist for recommendations tailored to your needs.

Benefits of Using Trash Pumps

Trash pumps offer a wide range of benefits that make them the preferred choice for tough dewatering and solids-handling tasks:

- Efficient solids handling: Move large debris, rocks, leaves, and fibrous materials without clogging

- High flow rates: Quickly remove large volumes of water, reducing downtime

- Versatile power options: Work with electric, gas, diesel, air, or solar power to suit different sites

- Robust durability: Built with tough materials to withstand abrasive environments

- Easy maintenance: Simple serviceability reduces operating costs

- Mobility: Many models are portable for rapid deployment

- Self-priming: Quick and easy to start, even after dry running

Ready to compare trash pump models and suppliers? Use our buyer’s guide below to evaluate key features and make an informed decision.

How to Choose the Best Trash Pump for Your Needs

Selecting the right trash pump involves evaluating several important factors. Answering these questions can help you narrow down your choices and ensure you purchase a pump that meets your performance and budget requirements:

- What is the maximum solid size? Determine the largest debris you expect to pump, and select a trash pump with an appropriate passage size.

- What flow rate do you need? Calculate the volume of water to be moved per minute or hour. High-capacity jobs require pumps with higher flow rates.

- How much total head (lift) is required? Consider both suction lift (vertical distance from water source to pump) and discharge head (vertical distance from pump to discharge point).

- What is the nature of the liquid? Is the water clean, or does it contain sand, sludge, chemicals, or corrosive substances? Choose materials and seals accordingly.

- Which power source is available? Electric pumps are ideal for sites with reliable power, while gasoline, diesel, or air-powered pumps provide flexibility in remote areas.

- What is your budget? Factor in both initial purchase price and long-term operating costs, including maintenance and parts.

- Do you need portability? Consider weight, size, and ease of transport if you’ll be moving the pump frequently.

Choosing the Right Trash Pump Manufacturer

When investing in a trash pump, selecting a reputable manufacturer is essential to ensure product quality, technical support, and long-term satisfaction. Here are practical tips to guide your selection process:

- Compare multiple manufacturers: Evaluate at least four different trash pump companies using a comprehensive directory of trash pump suppliers.

- Review manufacturer profiles: Each supplier should provide detailed information on experience, capabilities, certifications, and customer reviews.

- Use direct contact forms: Reach out for quotes, technical details, or to request custom solutions tailored to your application.

- Preview company websites: Use website preview tools to quickly assess specializations, product lines, and company reputation.

- Request references and case studies: Ask for documentation of successful projects in similar industries or use cases.

- Assess after-sales support: Ensure the manufacturer offers spare parts, maintenance services, and technical support.

Pro tip: Use our streamlined RFQ (Request for Quote) form to contact multiple trash pump manufacturers with the same inquiry, saving time and ensuring you receive competitive offers.

Frequently Asked Questions About Trash Pumps

What is the difference between a trash pump and a water pump?

Trash pumps are specifically engineered to handle water with large amounts of debris and solids, while standard water pumps are intended for clean or lightly contaminated water. Trash pumps have larger passageways, heavy-duty impellers, and reinforced components to prevent clogging and wear.

How do I maintain a trash pump?

Regular maintenance includes cleaning the strainer, checking and replacing seals and bearings, inspecting hoses and fittings, and flushing the pump after each use, especially if pumping corrosive or abrasive materials.

Can trash pumps handle chemicals or saltwater?

Some trash pumps are constructed with corrosion-resistant materials suitable for saltwater or mild chemicals. Always check the manufacturer’s specifications before use, and select a model with appropriate seals and coatings for harsh liquids.

What accessories are recommended for trash pumps?

Common accessories include reinforced suction and discharge hoses, quick-connect couplings, float switches, check valves, wheel kits for portability, and backup power supplies.

Get Expert Help and Start Your Trash Pump Project

Ready to select the best trash pump for your job? Explore our extensive directory of trash pump manufacturers for in-depth company profiles, product guides, and direct contact options. Whether you’re looking for an industrial trash pump for a municipal project or a portable trash pump for emergency flood control, our resources can help you find the ideal solution.

Still unsure? Use our live chat or call our pump experts for custom recommendations based on your specific requirements, site conditions, and budget. Discover why so many professionals trust us for their trash pump needs—start your search today!

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services