Because liquids are almost impossible to reduce in volume, they cannot be pressurized and therefore must be transported through other means. Centrifugal force causes substances including liquids to move away from their center of rotation; this force can be controlled and used to lift and convey liquid. Read More…

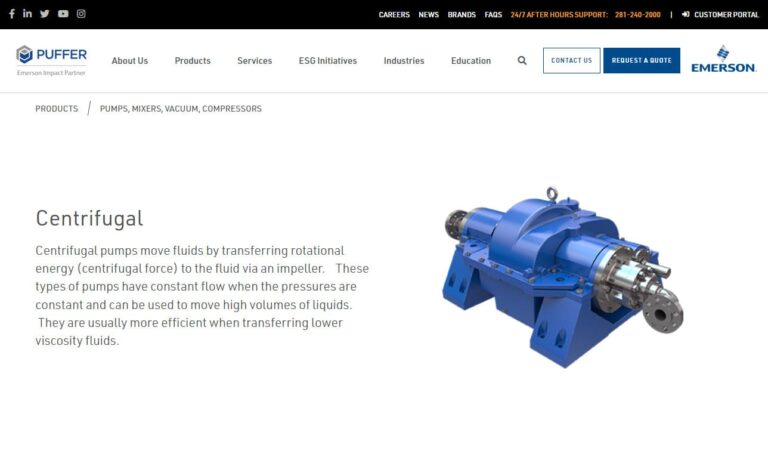

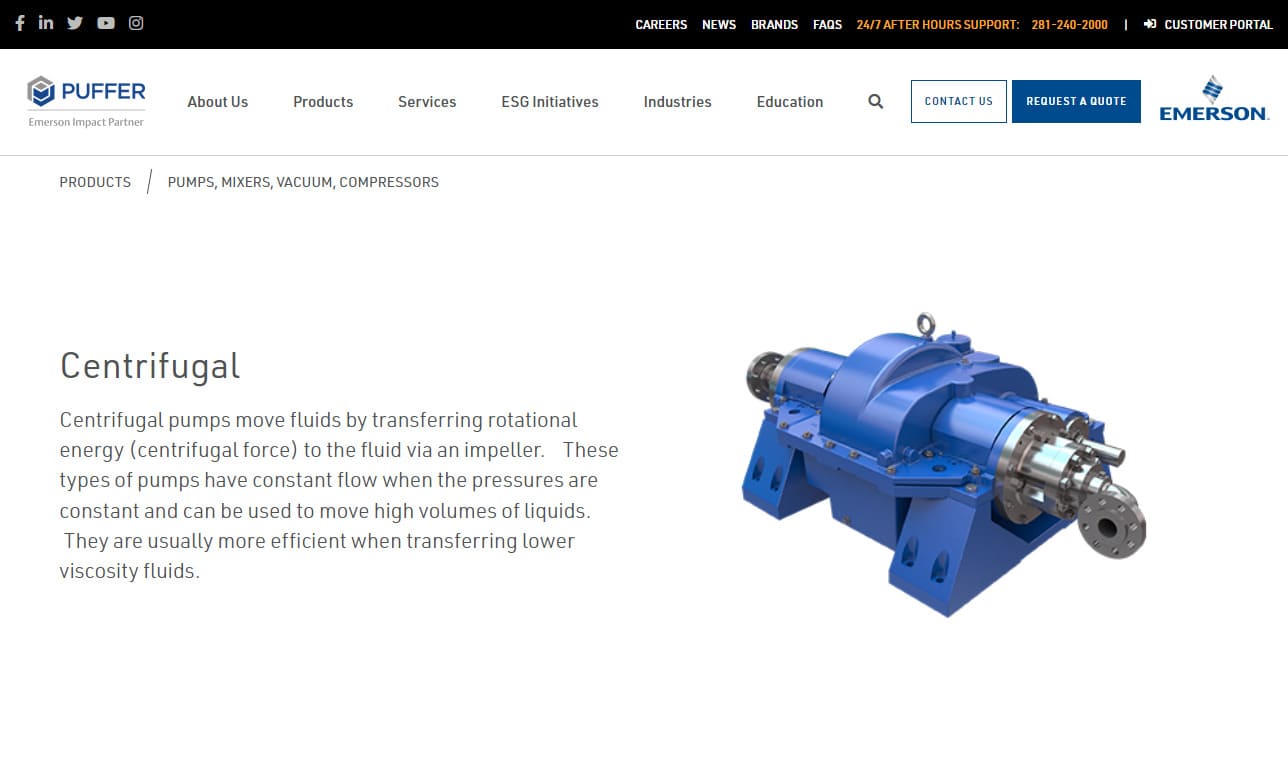

At Puffer Sweiven Rotating Equipment, we take pride in delivering dependable centrifugal pump solutions that keep critical operations running smoothly across process industries. We draw on decades of field experience and technical expertise to help our customers select, install, and maintain centrifugal pumps that meet demanding performance, reliability, and efficiency requirements.

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

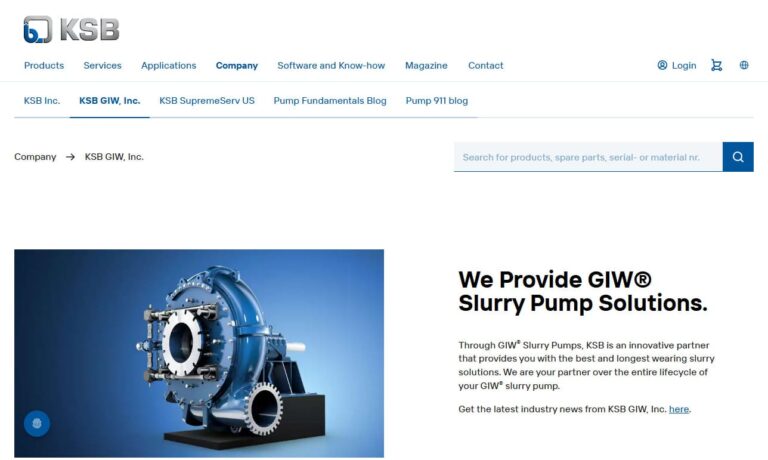

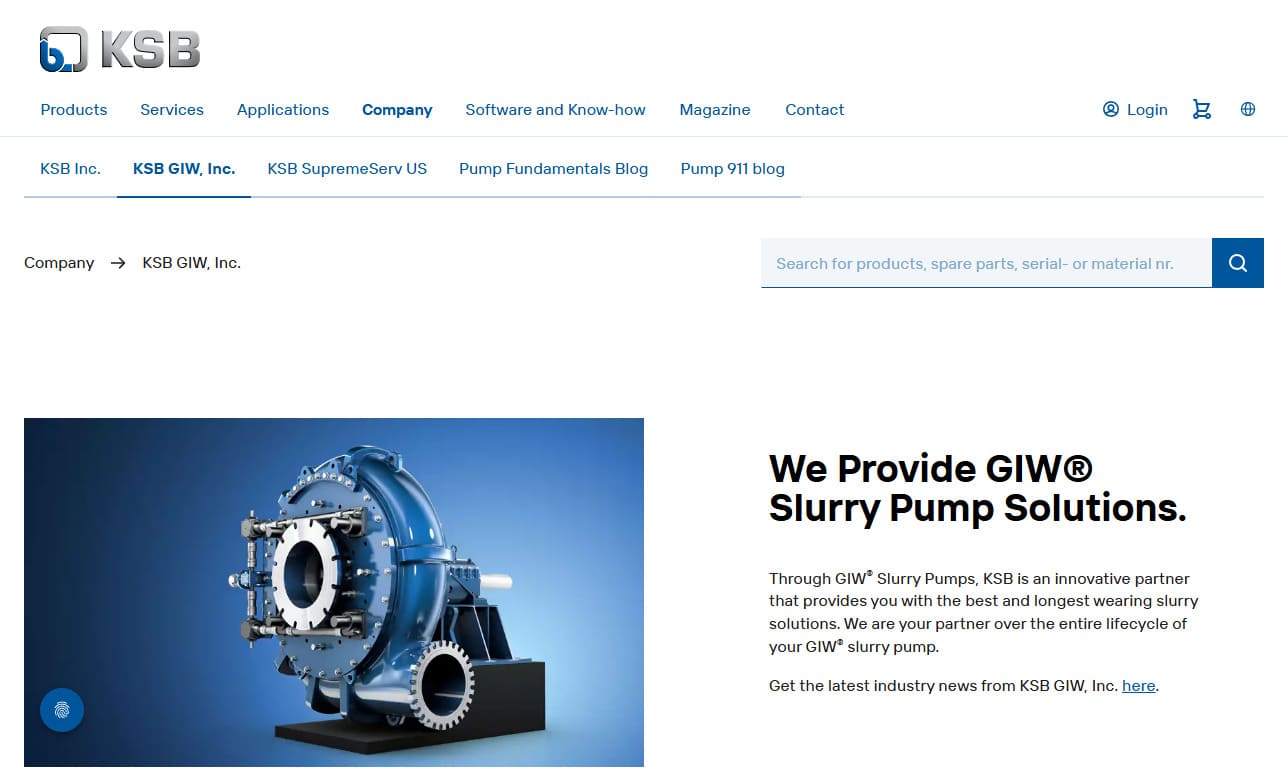

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

At Xylem, we take pride in advancing water technology through innovation and engineering excellence. Our centrifugal pumps are designed to deliver dependable, efficient performance across a broad range of industries and applications.

We are Pacer Pumps, a leading manufacturer of pumps and pumping solutions for a variety of applications. With over 50 years of experience in the industry, we are committed to providing our customers with high-quality, reliable products and exceptional service. At Pacer Pumps, we offer a wide range of pumps to suit a variety of needs, including centrifugal, self-priming, and hydraulic-driven pumps.

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

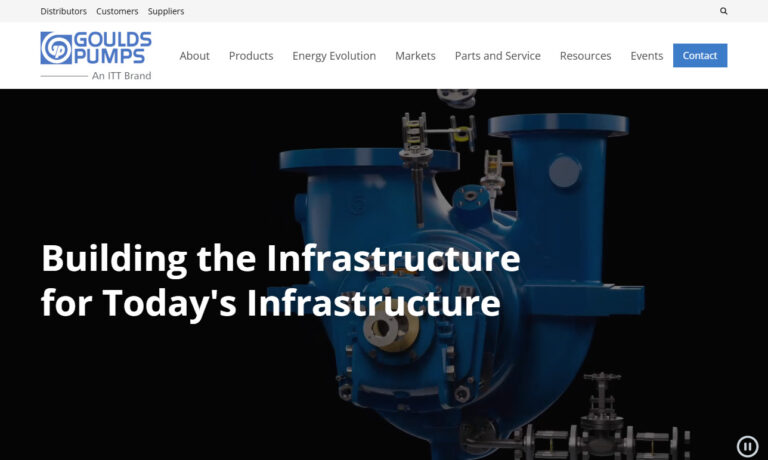

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

At Baker Hughes, we design and manufacture centrifugal pumps that deliver exceptional reliability and efficiency across a wide range of industrial and energy applications. We engineer our pump systems to move fluids safely and consistently under the most demanding conditions, from upstream oil and gas operations to power generation and process industries.

More Vertical Pump Manufacturers

Centrifugal Pump Manufacturers List

Vertical pumps are constructed from stainless steel, aluminum or cast iron and must be strong enough to withstand internal and external pressures. These pumps are most often used for lifting and transporting water, an application that finds many uses in residential, general purpose, industrial and commercial situations.

Centrifugal pumps are used in wastewater and sewage treatment plants to handle trash and refuse; certain heavy duty models can pump mixtures of solids that are suspended in liquid. As water pumps, vertical pumps are used for deep well pumping and move water from its underground source to buildings for human use or to prevent flooding or drainage issues.

If vertical pumps are made of strong corrosion resistant materials, they are able pump chemicals and acids which is a useful way of transporting hazardous liquids throughout a processing plant.

Vertical centrifugal pumps are simply designed machines. A casing called a volute contains a horizontal impeller mounted perpendicularly on an upright rotating shaft. The electric motor uses its mechanical energy to turn the impeller whose blades impart kinetic energy to the liquid as it begins to rotate up the casing.

Momentum and pressure carry the liquid (most commonly water) through the expanding volute until it exits through a discharge opening, sometimes at high velocities. Vertical pumps are located underground near the source of liquid which they move up to the surface. They are usually electric because a gas tank would be impractical to store and fill. The power cords are kept in a durable protective casing to prevent any leaks or damage.

One example of a vertical pump is an axial flow pump whose impeller is actually a kind of propeller that lifts the liquid in a direction parallel to the pump shaft instead of pushing it in a perpendicular direction like horizontal centrifugal pumps would. Vertical pumps are generally designed in a close-coupled arrangement where the motor and the pump are held in the same slim enclosure that can be lowered into a deep well hole. Another technique is to have the motor at ground level and install the pump underground.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services