A well pump is an electromechanical device installed after a well is drilled or dug. A well pump transports water from the well to another place. The well’s water is pumped through a pipe or jet by a centrifugal pump powered by an electric motor. The well pump raises water and delivers it to the authorized water system or home. The most widely used pumps today are jet pumps and submersible pumps. Both of these pumps use centrifugal force to lift water. Impellers (spinning rotors) produce a vacuum that propels water through the well casing into the distribution system. Read More…

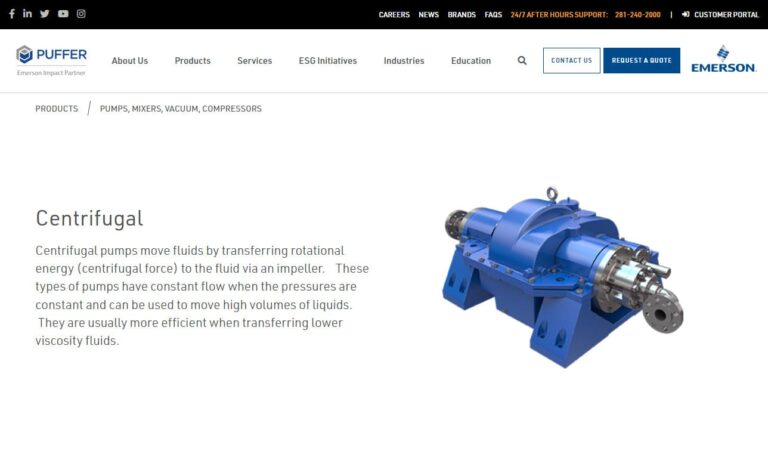

At Puffer Sweiven Rotating Equipment, we take pride in delivering dependable centrifugal pump solutions that keep critical operations running smoothly across process industries. We draw on decades of field experience and technical expertise to help our customers select, install, and maintain centrifugal pumps that meet demanding performance, reliability, and efficiency requirements.

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

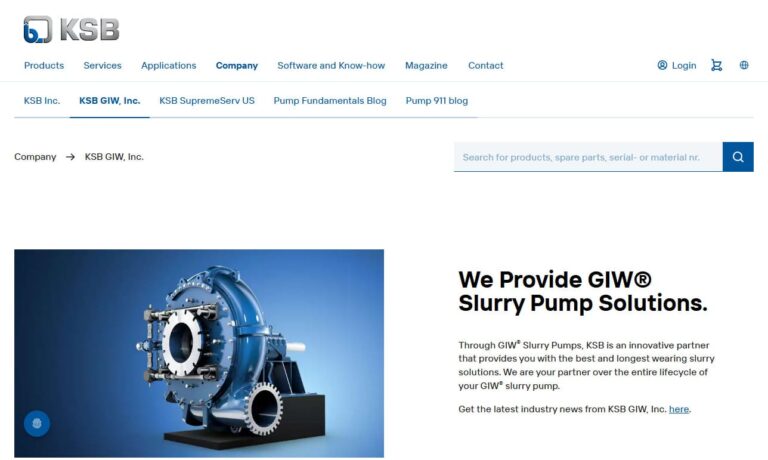

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

At Xylem, we take pride in advancing water technology through innovation and engineering excellence. Our centrifugal pumps are designed to deliver dependable, efficient performance across a broad range of industries and applications.

We are Pacer Pumps, a leading manufacturer of pumps and pumping solutions for a variety of applications. With over 50 years of experience in the industry, we are committed to providing our customers with high-quality, reliable products and exceptional service. At Pacer Pumps, we offer a wide range of pumps to suit a variety of needs, including centrifugal, self-priming, and hydraulic-driven pumps.

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

At Baker Hughes, we design and manufacture centrifugal pumps that deliver exceptional reliability and efficiency across a wide range of industrial and energy applications. We engineer our pump systems to move fluids safely and consistently under the most demanding conditions, from upstream oil and gas operations to power generation and process industries.

More Well Pump Manufacturers

Comprehensive Guide to Well Pumps: Types, Applications, and Supplier Selection

Selecting the right well pump is a crucial decision for homeowners, agricultural professionals, and commercial operators who rely on dependable access to groundwater. Understanding the different types of well pumps, their specific use cases, and key selection criteria will help you make an informed purchasing decision that ensures long-term water supply reliability and operational efficiency.

What Is a Well Pump?

A well pump is a mechanical device designed to extract water or other liquids—such as oil, gas, less hazardous chemicals, slurries, and wastewater—from underground sources. Well pumps are essential for a wide range of applications, including residential water wells, agricultural irrigation, mining operations, industrial fluid transfer, and fuel production. Choosing an appropriate well pump model and configuration is vital for optimizing flow rates, energy consumption, and long-term maintenance costs.

Key Factors to Consider When Choosing a Well Pump

When evaluating which well pump best suits your needs, several critical factors should guide your selection process:

- Well Depth: The depth of your well determines the pump type and capacity required. Different pumps are engineered for shallow, intermediate, or deep well installations.

- Water Demand: Estimate the daily water usage for your household, farm, or facility. Consider peak demand periods and ensure the pump delivers adequate gallons per minute (GPM).

- Fluid Type: Some well pumps are suitable for water only, while others can handle oil, gas, slurries, or chemically aggressive fluids. Confirm material compatibility for your application.

- Power Supply: Assess the available electrical infrastructure. Most residential and light commercial well pumps are powered by standard AC voltage, but some applications require alternative energy sources or higher voltage.

- Installation & Maintenance: Factor in accessibility for routine maintenance, repairs, or pump replacement. Submersible designs may require more effort to service compared to above-ground models.

- Budget & Lifecycle Costs: Consider not only the upfront cost, but also long-term efficiency, durability, and potential repair expenses.

Common Applications of Well Pumps

Well pumps are versatile and serve a variety of vital roles across diverse sectors. Some of the most common applications include:

- Residential Water Wells: Providing a reliable water source for homes in rural or off-grid locations.

- Agricultural Irrigation: Supplying water for crops, livestock, and greenhouse operations.

- Municipal and Community Water Systems: Supporting small towns, subdivisions, or shared wells.

- Mining & Oil Extraction: Pumping water, oil, or slurry from deep underground formations.

- Industrial Facilities: Handling process water, wastewater, and other specialized fluids.

- Emergency Backup Water Supply: Ensuring water access during utility outages or natural disasters.

Types of Well Pumps: Which One Is Right for You?

Are you wondering, "What kind of well pump do I need for my property?" Let’s explore the primary categories of well pumps and their ideal use cases to help you decide.

Shallow Well Pumps

Shallow well pumps are designed for wells with a static water level of 25 feet or less. These pumps are typically installed above ground and use suction pipes to draw water up from the well. Shallow well suction pumps are ideal for residential homes, cottages, and farms where groundwater is close to the surface, or where an artesian well is present.

- Maximum recommended depth: 25 feet (at sea level)

- Common applications: Small homes, garden irrigation, livestock watering

- Advantages: Simple installation, easy access for maintenance

- Limitations: Not suitable for deep or variable water tables

Jet Pumps: Shallow and Deep Well Variants

Jet pumps are a popular choice for both shallow and deep well applications. They operate by creating a vacuum with a jet assembly, which draws water upward through a suction pipe. There are two main types of jet pumps:

- Shallow Well Jet Pumps: Best suited for wells up to 25 feet deep. These pumps are efficient for small-scale water systems and are often installed in basements or mechanical rooms above the wellhead.

- Deep Well Jet Pumps: Capable of drawing water from depths of up to 100 feet. Deep well jet pumps use a two-pipe system—one for suction and one for returning water to the jet assembly. They are commonly used in rural and agricultural settings.

Performance considerations: As the pumping depth increases, the motor must work harder, which can reduce efficiency and increase energy costs. Additionally, jet pumps can be vulnerable to sand and sediment, which may cause wear or clogging over time.

Deep well jet pumps can either be installed at the surface or be partially submersible. Most rural properties rely on these electric well pumps to deliver water to homes, barns, and outbuildings. They are typically powered by standard household AC voltage and feature weather-resistant, die-cast housings for durability and longevity. Underground electrical cables allow remote or discreet installation.

Submersible Well Pumps

Submersible well pumps are the most common and versatile pump type for wells of all depths. As the name suggests, these pumps are installed underwater, deep inside the well casing. Submersible pumps are favored for their energy efficiency, quiet operation, and ability to deliver water from great depths—sometimes exceeding 400 feet.

- Ideal for deep wells and high-demand water systems

- Sealed, waterproof design minimizes risk of electrical failure

- Motors drive impellers that force water up the well pipe to the surface

- Low-maintenance and long-lasting, but servicing requires removal from the well

- Available in various horsepower ratings and flow capacities to suit household, commercial, and agricultural needs

Submersible well pumps can be used in single-family homes, multi-unit residential complexes, farms, irrigation systems, and industrial settings. While they are typically more expensive upfront and may be susceptible to corrosion in aggressive water conditions, they are less prone to mechanical failure compared to above-ground or jet pumps.

Other Types of Well Pumps and Accessories

In addition to jet and submersible pumps, there are specialized well pump designs for unique applications:

- Convertible Jet Pumps: Adaptable for both shallow and deep wells using interchangeable ejector kits.

- Hand Pumps: Used for off-grid, emergency, or backup water supply where electricity is unavailable.

- Solar-Powered Well Pumps: An energy-efficient choice for remote installations, off-grid living, or sustainable agriculture.

- Constant Pressure Systems: Advanced controllers that maintain steady water pressure regardless of demand.

- Well Pump Control Boxes and Pressure Switches: Essential for automating pump operation and protecting against dry run or overload conditions.

Looking to compare different well pump technologies? Learn more about various pump types and manufacturers to find the right solution for your specific needs.

Benefits of Choosing the Right Well Pump

Selecting the optimal well pump delivers significant advantages, including:

- Reliable Water Supply: Ensures consistent access to water for drinking, cleaning, irrigation, or industrial processes.

- Energy Efficiency: Modern well pumps are engineered for maximum hydraulic efficiency, reducing energy bills and environmental impact.

- Longevity and Durability: High-quality pumps withstand harsh environments, abrasive water, and heavy usage with minimal maintenance.

- Customizable Performance: Wide range of flow rates, pressures, and power options available to suit virtually any application.

- Low Maintenance: Many submersible and jet pumps feature corrosion-resistant materials and sealed motors for trouble-free operation.

- Safe Operation: Built-in safety switches, overload protection, and dry-run prevention ensure safe, reliable pumping.

How to Choose the Right Well Pump Supplier

To achieve the best results when purchasing a well pump, it’s essential to select a reputable, knowledgeable supplier. Here are actionable steps and decision factors for buyers evaluating well pump manufacturers and distributors:

- Compare Multiple Companies: Consult at least 4–5 well pump suppliers to evaluate product offerings, technical support, and pricing. Use supplier directories and industry portals for a curated list of trusted sources.

- Review Business Profiles: Each supplier should provide a detailed profile highlighting their experience, manufacturing capabilities, and market focus (residential, agricultural, industrial, etc.).

- Request Quotes and Specifications: Use contact forms or RFQ tools to request detailed product specifications, pricing, and lead times. This allows you to compare apples-to-apples before making a purchase.

- Check Website and Product Information: Explore each supplier’s website for technical datasheets, installation guides, certifications, and case studies. Our proprietary website previewer can give you a quick overview of each company’s specialization.

- Assess After-Sales Support: Inquire about warranty coverage, field service availability, and technical support resources. Reliable customer service is vital for long-term satisfaction.

- Read Customer Reviews: Look for testimonials and independent reviews to gauge product reliability and supplier responsiveness.

Want to compare suppliers side by side? Use our simple RFQ form to contact multiple well pump businesses and receive competitive quotes tailored to your project requirements.

Frequently Asked Questions About Well Pumps

- How do I size a well pump for my home? Calculate your peak water demand in gallons per minute (GPM) based on the number of fixtures and appliances. Match the pump’s flow rate and total dynamic head to your well’s depth and required pressure.

- What’s the difference between a submersible pump and a jet pump? Submersible pumps are installed below the water level inside the well and push water to the surface, while jet pumps are installed above ground and pull water upward using suction.

- How long does a typical well pump last? With proper installation and maintenance, submersible well pumps can last 8–15 years, while jet pumps often operate reliably for 5–10 years. Lifespan varies with water quality, usage, and operating conditions.

- Can I use a solar-powered well pump? Yes, solar well pumps are increasingly popular for remote, off-grid, or sustainable water systems. They are efficient and environmentally friendly, ideal for agricultural and residential use.

- What maintenance does a well pump require? Routine tasks include checking pressure switches, inspecting electrical connections, monitoring for leaks, and testing water quality. Deep well pumps may require periodic removal for inspection and repair.

Top Tips for Purchasing and Installing a Well Pump

- Always verify the well’s static and pumping water levels before selecting a pump.

- Choose a pump material (stainless steel, cast iron, thermoplastic) that resists corrosion in your local water conditions.

- Install a properly sized pressure tank to prevent frequent cycling and prolong pump life.

- Consider variable speed or constant pressure systems for consistent water flow and energy savings.

- Work with licensed installers or certified contractors to ensure code compliance and warranty protection.

- Regularly monitor pump performance and schedule preventive maintenance to avoid costly breakdowns.

Troubleshooting Common Well Pump Problems

Having trouble with your well pump? Here are some common issues, causes, and quick solutions:

- Pump not starting: Check power supply, pressure switch, and circuit breakers.

- No water or low pressure: Inspect for leaks, clogged filters, or a faulty check valve.

- Pump runs continuously: Possible cause is pressure tank failure, pipe leaks, or damaged pressure switch.

- Pump cycles on and off rapidly: Pressure tank may be waterlogged or undersized.

- Sand or sediment in water: May indicate a failing well screen or pump installed too close to the well bottom.

Still have questions? Contact a well pump expert for personalized troubleshooting and technical support.

Well Pump Installation and Replacement: What to Expect

Proper installation is key to maximizing the performance and lifespan of your well pump. Here’s a step-by-step overview of what to expect during the process:

- Site assessment and well measurement: Confirm depth, static level, and pump requirements.

- Pump and equipment selection: Choose the right size, type, and accessories for your application.

- Electrical and plumbing setup: Ensure safe wiring, grounding, and pressure tank installation.

- Pump placement: Lower submersible pumps into the well or mount jet pumps above ground.

- System testing: Check for leaks, confirm flow rate and pressure, and adjust controls as needed.

- Owner training: Learn routine maintenance, troubleshooting, and seasonal care to protect your investment.

Considering a new well pump installation or a replacement? Get matched with certified installers and receive expert guidance for a seamless process.

Conclusion: Find the Best Well Pump for Your Needs

Whether you require a shallow well pump for a small property, a high-capacity submersible well pump for agricultural irrigation, or an industrial-grade jet pump for deep water extraction, understanding your options is the first step to a reliable, efficient water system. Use our supplier comparison tools, detailed product guides, and expert resources to make an informed decision and ensure years of trouble-free operation.

Ready to find the perfect well pump or need help specifying a system? Request a quote today and connect with leading well pump manufacturers and distributors who can meet your project’s unique requirements.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services